GLASS REINFORCED CONCRETE - GRC

What is GRC?

GFRC is similar to chopped fiberglass (the kind used to form boat hulls and other complex three-dimensional shapes), although much weaker. It’s made by combining a mixture of fine sand, cement, polymer (usually an acrylic polymer), water, other admixtures and alkali-resistant (AR) glass fibers. Many mix designs are available online, but you’ll find that all share similarities in the ingredients and proportions used.

Some of the many benefits of GFRC include:

- Ability to Construct Lightweight Panels– Although the relative density is similar to concrete, GFRC panels can be much thinner than traditional concrete panels, making them lighter.

- High Compressive, Flexural and Tensile Strength– The high dose of glass fibers leads to high tensile strength while the high polymer content makes the concrete flexible and resistant to cracking. Proper reinforcing using scrim will further increase the strength of objects and is critical in projects where visible cracks are not tolerable.

The Fibers in GFRC- How They Work

The glass fibers used in GFRC help give this unique compound its strength. Alkali resistant fibers act as the principle tensile load carrying member while the polymer and concrete matrix binds the fibers together and helps transfer loads from one fiber to another. Without fibers GFRC would not possess its strength and would be more prone to breakage and cracking.

Casting GFRC

Commercial GFRC commonly uses two different methods for casting GFRC: spray up and premix. Let’s take a quick look at both as well as a more cost effective hybrid method.

Spray-Up

The application process for Spray-up GFRC is very similar to shortcrete in that the fluid concrete mixture is sprayed into the forms. The process uses a specialized spray gun to apply the fluid concrete mixture and to cut and spray long glass fibers from a continuous spool at the same time. Spray-up creates very strong GFRC due to the high fiber load and long fiber length, but purchasing the equipment can be very expensive ($20,000 or more).

Premix

Premix mixes shorter fibers into the fluid concrete mixture which is then poured into molds or sprayed. Spray guns for premix don’t need a fiber chopper, but they can still be very costly. Premix also tends to possess less strength than spray-up since the fibers and shorter and placed more randomly throughout the mix.

Hybrid

One final option for creating GFRC is using a hybrid method that uses an inexpensive hopper gun to apply the face coat and a handpacked or poured backer mix. A thin face (without fibers) is sprayed into the molds and the backer mix is then packed in by hand or poured in much like ordinary concrete. This is an affordable way to get started, but it is critical to carefully create both the face mix and backer mix to ensure similar consistency and makeup. This is the method that most concrete countertop makers use.

Different Types of Fiber Reinforced Concrete

1. Steel Fiber Reinforced Concrete

A no of steel fiber types are available as reinforcement. Round steel fiber the commonly used type are produced by cutting round wire in to short length. The typical diameter lies in the range of 0.25 to 0.75mm. Steel fibers having a rectangular c/s are produced by silting the sheets about 0.25mm thick.

Fiber made from mild steel drawn wire. Conforming to IS:280-1976 with the diameter of wire varying from 0.3 to 0.5mm have been practically used in India.

Round steel fibers are produced by cutting or chopping the wire, flat sheet fibers having a typical c/s ranging from 0.15 to 0.41mm in thickness and 0.25 to 0.90mm in width are produced by silting flat sheets.

Deformed fiber, which are loosely bounded with water-soluble glue in the form of a bundle are also available. Since individual fibers tend to cluster together, their uniform distribution in the matrix is often difficult. This may be avoided by adding fibers bundles, which separate during the mixing process.

2. Polypropylene Fiber Reinforced (PFR) cement mortar and concrete

Polypropylene is one of the cheapest & abundantly available polymers polypropylene fibers are resistant to most chemical & it would be cementitious matrix which would deteriorate first under aggressive chemical attack. Its melting point is high (about 165 degrees centigrade). So that a working temp. As (100 degree centigrade) may be sustained for short periods without detriment to fiber properties.

Polypropylene fibers being hydrophobic can be easily mixed as they do not need lengthy contact during mixing and only need to be evenly distressed in the mix.

Polypropylene short fibers in small volume fractions between 0.5 to 15 commercially used in concrete.

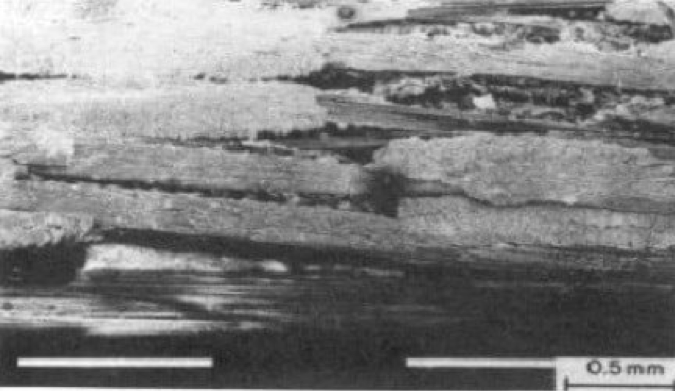

Fig.1: Polypropylene fiber reinforced cement-mortar and concrete

3. GFRC – Glass Fiber Reinforced Concrete

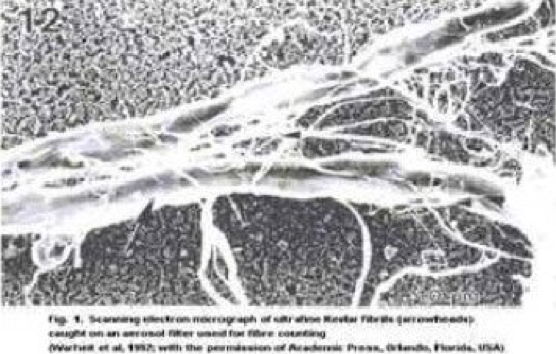

Glass fiber is made up from 200-400 individual filaments which are lightly bonded to make up a stand. These stands can be chopped into various lengths, or combined to make cloth mat or tape. Using the conventional mixing techniques for normal concrete it is not possible to mix more than about 2% (by volume) of fibers of a length of 25mm.

The major appliance of glass fiber has been in reinforcing the cement or mortar matrices used in the production of thin-sheet products. The commonly used verities of glass fibers are e-glass used. In the reinforced of plastics & AR glass E-glass has inadequate resistance to alkalis present in Portland cement where AR-glass has improved alkali resistant characteristics. Sometimes polymers are also added in the mixes to improve some physical properties such as moisture movement.

Fig.2: Glass-fiber reinforced concrete

4. Asbestos Fibers

The naturally available inexpensive mineral fiber, asbestos, has been successfully combined with Portland cement paste to form a widely used product called asbestos cement. Asbestos fibers here thermal mechanical & chemical resistance making them suitable for sheet product pipes, tiles and corrugated roofing elements. Asbestos cement board is approximately two or four times that of unreinforced matrix. However, due to relatively short length (10mm) the fiber have low impact strength.

Fig.3: Asbestos fiber

5. Carbon Fibers

Carbon fibers from the most recent & probability the most spectacular addition to the range of fiber available for commercial use. Carbon fiber comes under the very high modulus of elasticity and flexural strength. These are expansive. Their strength & stiffness characteristics have been found to be superior even to those of steel. But they are more vulnerable to damage than even glass fiber, and hence are generally treated with resign coating.

Fig.4: Carbon fibers

6. Organic Fibers

Organic fiber such as polypropylene or natural fiber may be chemically more inert than either steel or glass fibers. They are also cheaper, especially if natural. A large volume of vegetable fiber may be used to obtain a multiple cracking composite. The problem of mixing and uniform dispersion may be solved by adding a superplasticizer.

Fig.5: Organic fiber